Right into the bell, the carving or etching company names, trademarks, logo and the wording of the shell at the clock, table case back, clasp, strap and bezel are indispensable. To meet the different needs of the market and customers, manufacturers introduced different types of carving ways for customers to choose, for example, Stamping sculpture, etching and laser engraving.

According to the manufacturers interviewed said, each carving method involves different steps and have their identity. The use of oil to steel or chrome steel engraved Seal Seal carving patterns play a very traditional carving methods. One manufacturer interviewed said the general's words in the Stamping is 0.9 mm high, and the most elaborate was only 0.5 mm. In addition, the handling of electric furnace, but also enhance the effect of Seal Keke play clarity and texture of the bump the words and patterns, so become increasingly popular.

Etching is another to carve and smooth the effect of more detailed methods of lettering. However, this approach involving chemical liquid, to a certain degree of stress is not very environmentally friendly. However, the respondents are either seriously to ensure that every one etching process, that is, drawings or real version, screen printing film, etching first oil is done right. Table etched case back only a few microns deep lines, while the bell rings will be etched deeper.

Based on ever-changing styles of watches and clocks, watches accessories also need to constantly change the design of the sculpture section, customers demanded fast delivery and flexible production process. The birth of laser engraving to help manufacturers and customers to resolve these issues. Interviewed manufacturers of the respective two are engaged in the laser engraving business, is to provide a laser engraving service, the other is the production of laser engraving machine. Two manufacturers also agreed to laser engraving can help produce high-quality and stable products.

First of all, laser engraving can be applied to any material, whether it is stainless steel, copper, aluminum, alloys, ceramics, silver or plastic will do. Secondly, the high speed laser engraving, and reliable. For example, carving a speed of up to 1,500 straight cotton mm / sec, and when the pattern recognition, engraving machine can operate 24 hours a day to ensure quick delivery. In addition, laser engraving is a computerized, you can control each one carved out of the pattern and the words are absolutely the same, smooth and detailed. The smallest laser engraving font that is only about 1.064 microns. In addition, laser engraving does not contain chemical materials and pollutants, it is quite environmentally friendly and economical method.

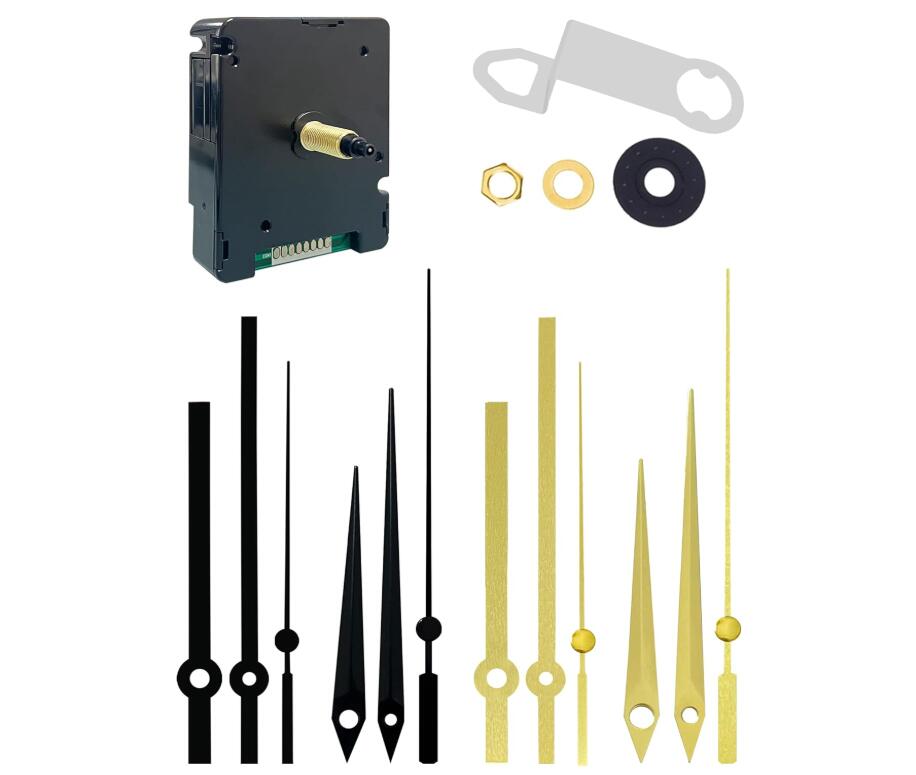

- Sweep clock movement

- Clock hands

- High torque clock movement

- Skeleton clock movement

- Radio controlled clocks

- Pendulum clock movement

- 24 hours clock movement

- Tide clock movement

- DIY clock movement

- Round clock movement

- Quartz clock movement

- Clock inserts

- Watch inserts

- Clock parts

- Clock dials

- Wall clocks

- Plastic clock movements

- Toy clock movements

- Hook clock movement

- Alarm clock

- Clock movement

- Movements package

- Clock hands catalog

Sitemap Admin Powered by: hkwww.cn

Tel: 86-769-85532891 E-mail: talent@hengrongclock.com.cn http://www.clockmovements.cn

Keywords: clock movement, clock parts, clock hands, clock mechanism, clock accessories, cuckoo clock, alarm clock, insert clock